-

Haber Akışı

- KEŞFEDIN

-

Sayfalar

-

Etkinlikler

-

Bloglar

-

Hakkımızda

Hakkımızda

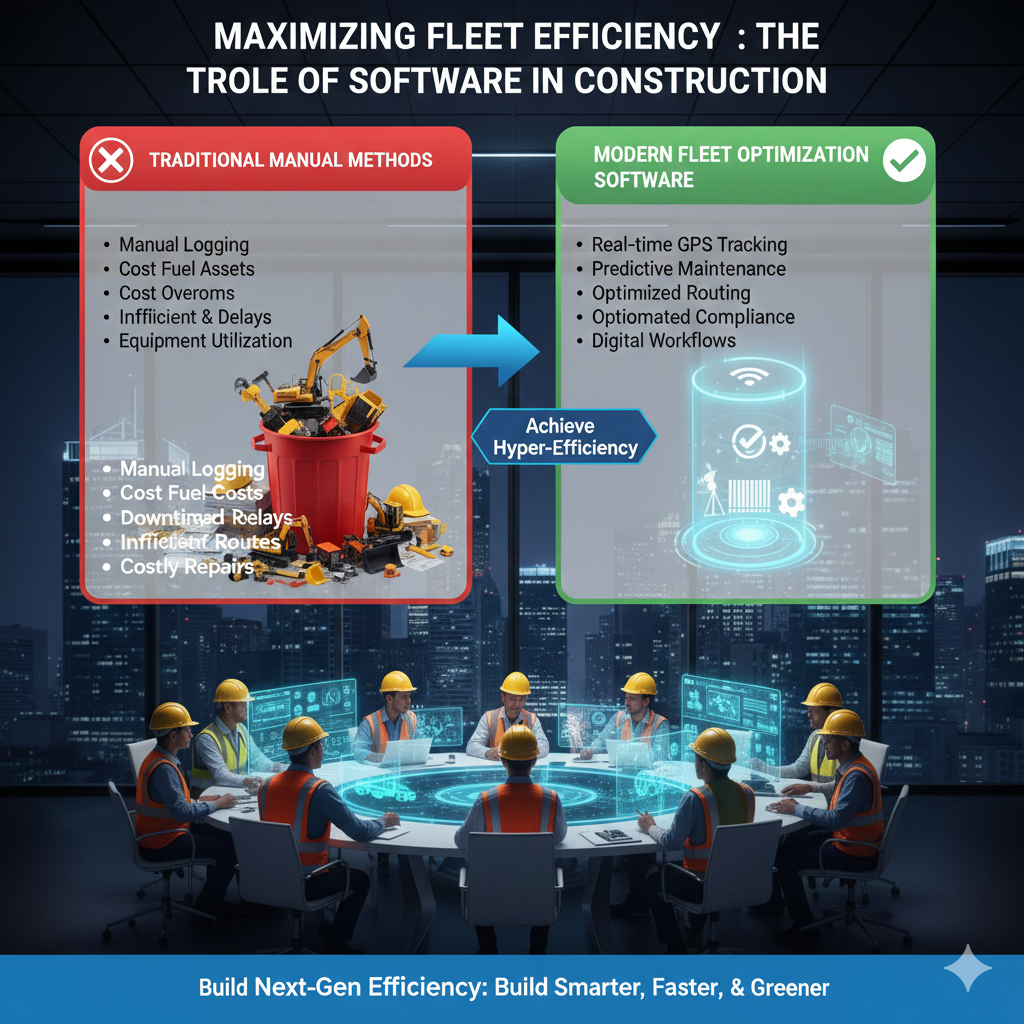

Maximizing Fleet Efficiency: The Role of Software in Construction

In the construction industry, fleet management is a complex and essential task. With a wide range of equipment, tools, and machinery involved in every project, keeping track of the status, location, and maintenance of each asset is crucial for maintaining efficiency and ensuring project success.

With growing demands and an increasing fleet of equipment, traditional methods of fleet management often involving spreadsheets, paper logs, and manual checks are no longer effective.

This is where fleet management software comes into play. By integrating technology into the fleet management process, businesses can optimize their operations, reduce costs, and improve overall efficiency. In this article, we explore how construction fleet management software is transforming the industry, helping businesses streamline their fleet operations, and contributing to smoother project execution.

The Complexities of Fleet Management in Construction

Construction projects often require a variety of equipment, including cranes, bulldozers, excavators, loaders, and more. Managing these assets is no small feat. The complexity increases as businesses often operate across multiple sites, each with varying equipment requirements. For many construction companies, this creates challenges in tracking asset availability, ensuring timely maintenance, and maintaining equipment efficiency.

Common problems in traditional fleet management:

-

Manual tracking: Keeping track of equipment through spreadsheets or paper logs is prone to errors, and critical information can be overlooked or delayed.

-

Lack of real-time visibility: Without real-time tracking of equipment, managers may not know the exact location or operational status of equipment, leading to inefficiencies.

-

High maintenance costs: Failing to schedule and track equipment maintenance leads to costly breakdowns and delays, as well as equipment underperformance.

-

Underutilization or overuse of equipment: Without effective resource allocation, some equipment may be underused, while others are overworked, leading to increased wear and tear.

Switching to fleet management software helps overcome these challenges by providing real-time access to critical data and streamlining processes, ensuring that assets are utilized effectively and maintained on time.

How Construction Fleet Management Software Improves Efficiency

Construction fleet management software is designed to automate and streamline various aspects of fleet management. From tracking the location and usage of assets to scheduling maintenance and repairs, this software helps construction companies keep their fleets running smoothly and efficiently.

1. Real-Time Equipment Tracking

One of the primary features of fleet management software is the ability to track equipment in real time. GPS technology integrated into the software allows managers to see the exact location of each asset, whether it’s on-site or being transported to a new location. This real-time visibility ensures that equipment is available when needed and prevents it from being lost or misplaced.

How real-time tracking enhances operations:

-

Improved asset allocation: Managers can allocate equipment to the right job site at the right time, minimizing delays caused by unavailable equipment.

-

Reduced theft: With real-time tracking, the risk of theft is reduced, as businesses can monitor the movement of equipment and receive alerts if it is moved without authorization.

-

Faster response time: In the event of a breakdown or emergency, managers can quickly locate the equipment and assess the situation, reducing downtime.

By providing accurate, up-to-the-minute data on equipment location and usage, fleet management software enhances the efficiency of day-to-day operations.

2. Proactive Maintenance Scheduling

Maintenance is a crucial aspect of fleet management, and regular maintenance is key to keeping equipment in optimal working condition. With fleet management software, businesses can automate and schedule maintenance tasks based on equipment usage, hours of operation, and manufacturer guidelines.

How scheduled maintenance saves time and money:

-

Preventive maintenance: By scheduling maintenance in advance, businesses can avoid unexpected equipment breakdowns, reducing costly emergency repairs.

-

Extended equipment life: Regular maintenance extends the lifespan of machinery, allowing businesses to maximize the return on investment from their fleet.

-

Optimized downtime: Instead of waiting for equipment to fail, businesses can plan downtime for maintenance, reducing the impact on productivity.

By automating maintenance schedules, fleet management software ensures that equipment remains in top condition, helping businesses avoid unnecessary repair costs and keeping their fleets running efficiently.

3. Improved Resource Allocation

Effective resource allocation is essential for maximizing productivity on construction projects. Construction fleet management software helps businesses track the usage and availability of equipment, ensuring that the right assets are deployed to the right job sites at the right time.

How better resource allocation improves operations:

-

Maximized equipment utilization: Managers can assess which equipment is being underutilized and redeploy it to other job sites where it is needed, improving overall fleet efficiency.

-

Reduced rental costs: By optimizing the use of owned equipment, businesses can reduce the need for expensive equipment rentals, lowering project costs.

-

Streamlined scheduling: With a clear view of equipment availability, businesses can avoid scheduling conflicts and ensure that machines are used as efficiently as possible.

With improved visibility and data-driven insights, fleet management software enables businesses to allocate resources more effectively, leading to smoother project execution and improved productivity.

4. Data-Driven Decision Making

The data provided by construction fleet management software is invaluable for making informed decisions. By analyzing usage patterns, maintenance history, fuel consumption, and other key metrics, businesses can make better decisions about equipment purchases, leases, and replacements.

How data insights benefit businesses:

-

Informed purchasing decisions: Businesses can assess which equipment is most cost-effective to repair versus replace, helping them make smarter investment decisions.

-

Optimized fleet size: By understanding equipment utilization and performance, companies can better determine the optimal size of their fleet, avoiding overinvestment in underused assets.

-

Cost reduction: Detailed data on fuel consumption, maintenance costs, and operational efficiency allows businesses to identify areas where they can reduce costs and improve profitability.

Data-driven decision-making empowers managers to optimize their fleet and operations, leading to better financial outcomes for the business.

5. Enhanced Communication and Coordination

Construction fleet management software improves communication between team members, site managers, and other stakeholders by providing a centralized platform for equipment data. This enhanced communication streamlines operations and ensures that everyone involved has access to the same real-time information.

How software improves communication:

-

Centralized platform: All team members can access real-time information on equipment location, usage, and maintenance schedules, reducing miscommunication.

-

Better coordination: With a unified system, teams can coordinate equipment usage and ensure that resources are deployed efficiently across multiple job sites.

-

Faster decision-making: With immediate access to critical data, managers can make quicker, more informed decisions, reducing delays and improving productivity.

By improving communication and coordination, fleet management software helps ensure that projects stay on track and are completed on time.

Conclusion

Managing a construction fleet is a challenging but essential task for businesses in the industry. Construction fleet management software offers an efficient, data-driven solution for optimizing equipment usage, reducing costs, and improving productivity.

By providing real-time tracking, automating maintenance schedules, and offering valuable insights for decision-making, this software helps businesses maximize the efficiency of their fleet and streamline operations.

As the construction industry continues to evolve, adopting construction fleet management software is no longer optional but a necessity for companies looking to stay competitive. Whether you are managing a small fleet or overseeing operations across multiple job sites, this software offers the tools and capabilities needed to improve fleet efficiency, reduce downtime, and ultimately achieve project success.

- Profesyonel Blog Haberleri

- Yerel Haberler

- Burdur Sektör Haberleri

- Burdur Mesleki Haberler

- Burdur Sosyal Medya Haberleri